Seafood Factory & Plant Cleaning

Fish & Seafood Processing Cleaning

BioGiene are Fish and Seafood Factory cleaning specialists. With decades of experience and an international team, tap into our extensive workforce and buying power to improve your current cleaning solution.

Our knowledge base and experience in Fish and Seafood Plant Cleaning makes BioGiene an ideal candidate to protect your brand and save you money.

Highly qualified and dedicated account managers, with a full working knowledge of Fish and Seafood cleaning requirements, develop quality processes and services tailor made for your facility. Utilising the encrypted and secure Biogiene Dashboard, are able to review water and chemical usage, temperature monitoring, labour safety and analysis as well as other site-specific information.

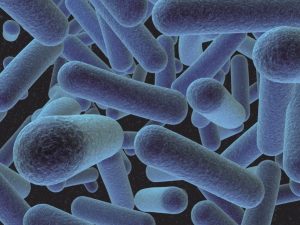

Fish and Seafood present unique challenges to meat processing plants as opposed to other food processing plants and require our teams to be specifically trained. Seafood processing involves a high chance of bacteria formation, and a regular, professional team familiar with your business, the facility and quality of processing is integral to removing bacteria from surfaces and utensils and to promote food safety.

Visit our case studies section and learn how BioGiene’s clients are saving money, protecting their brand and improving their processes!

Integrated Management System

- BioGiene work collaboratively with you to provide an Integrated Management System tailored specifically to your Fish and Seafood processing cleaning and Food Safety requirements.

- BioGiene IMS team & operational staff are recruited from the most experienced pool of industry professionals to ensure Work Instructions & Risk Assessments are delivered at the highest standard.

- This ensures that the sanitation and hygiene program delivered to site meets all your auditable and legislative requirements.

- BioGiene will liaise with your people to develop, measure and manage KPIs around food safety, chemicals, water, and other core metrics.

Cleaning Systems (OPCS & CIP)

BioGiene’s dedication to continuous improvement leads to opportunities for:

-

- Water reductions

- Chemical efficiency

- Labour efficiency

BioGiene utilises our advanced methods in each facility while our network of sophisticated business partners and relationships to add further value to your cleaning.

Click here to learn more about our suppliers.

Proven Return on Investment

Our reputation and decades of experience speak for themselves.

With specialised equipment, proactive and transparent reporting and a unique recruiting and HR model, we firmly believe BioGiene will be able to show a significant return on investment for your factory cleaning.

If you are interested in learning more, please book a consult with one of our team members today!

book a consult

Happy clients include;

Read More

Food safety legislation is closely complied with to ensure zero chance of contamination in both processing and store areas.

Although other processes may appear similar, a fish and seafood processing plant will differ from other food and other meat processing plants and require different approaches and chemicals when cleaning. Food contact surfaces need constant attention and rinsing so as to avoid any possibility of cross contamination between beef and pork, poultry and seafood, raw meat or cooked, processed or liquid. Cleaning methods will vary depending on temperature as seafood will require different storage temperatures than other meats. Foods might be frozen or ready to eat. Whatever the case, food safety is paramount and product quality always the highest and fit for human consumption. You also have to determine shelf life, manufacturer’s instructions and comply with food safety standards. And it all has to fit together perfectly. Having the expertise to identify these differences and situations, we ultimately make your life so much easier by getting the cleaning process and solutions right, all the time, providing services that create solutions so you can run your business at capacity.

There are many factors unique to food safety with regards to fish and seafood products. As an example:

- manual cleaning services

- water treatment cleaning

- contamination and bacteria

- essential cold rinsing facilities

- committed bacteria control systems for sanitation effectiveness

A working day cleaning and processing fish and seafood presents many challenges, as with in any food factory. We provide capable hygiene solutions, equipment solutions, process solutions and effective productive and waste cleaning solutions and cleaning services in any demanding food production project, operation or company.

Factory Clean

Targeting Listeria Monocytogenes

Contact our emergency cleaning team by emailing [email protected].

Listeria Monocytogenes is one of the leading causes of death from foodborne illness? Next to creating nausea, vomiting, aches, fever and diarrhoea, it can also spread through the bloodstream to the nervous system, resulting in meningitis which can be fatal. Listeria Monocytogenes cases are not linked to one specific type of food; they have been traced back to e.g. raw or under pasteurized milk; smoked fish and other seafood; meats, cheeses (especially soft cheeses) and raw vegetables.

Once you have Listeria Monocytogenes in your factory, you will find it is very difficult to get rid of it. The underlying reasons for this are that Listeria Monocytogenes tolerates salty environments and cold temperatures, it can even continue to grow at temperatures as low as -1.5˚C. Next to this is known that Listeria Monocytogenes will even survive temperatures as low as -25˚C (and lower). So tactics like keeping your product frozen at very low temperatures for a while as a kill step does not work with Listeria Monocytogenes. We must note here that although some manufacturers are using freezing as a kill step this practice should be taken with a lot of precaution.

Once you have Listeria Monocytogenes in your factory, you will find it is very difficult to get rid of it. The underlying reasons for this are that Listeria Monocytogenes tolerates salty environments and cold temperatures, it can even continue to grow at temperatures as low as -1.5˚C. Next to this is known that Listeria Monocytogenes will even survive temperatures as low as -25˚C (and lower). So tactics like keeping your product frozen at very low temperatures for a while as a kill step does not work with Listeria Monocytogenes. We must note here that although some manufacturers are using freezing as a kill step this practice should be taken with a lot of precaution.

Role in Food Processing

This bacteria has a growth range in temperatures of -4°C to 37°C. As a result, Listeria is commonly found in refrigerated foods, both processed and unprocessed. Commonly found in raw milk: is also found in common food groups.

This bacteria has been researched in depth, esp. with high mortality associated with young and elderly.

Those most susceptible to infection are pregnant women, alcoholics, young children, and the elderly, and immunocompromised individuals.

USA, 1993, in 1092 cases, 248 died.

In USA, acceptable limit = absence in 25g samples.

In EEC, cheeses = nil. Absence in 1g of other products.

Canada. Absence in high risk foods. Low risk = Category 3 foods <102/g.

France, absence in 25g samples for at risk individuals.

- pH: 4.1 – 9.6 Optimum 6.0 – 8.0

- Temperature: Minimum 1oC, Optimum Growth 10oC to 40oC

-

Pathogenic strains produce a β haemolysin, Listeriolysin O.

Found in decaying vegetation, and in soils, animal faeces, sewerage, silage and water.

Spreads both aerially and mechanically.

Is secreted and excreted by animals.

Is secreted by infected man and colonizes in intestines.

Associated with animal products; milk, meat, carcass, dairy products.

Screen staff for bacteria and any residing on farms, plots, holdings.

Check crates for biofilm, cleanliness, sanitation and rotation.

Pay particular attention to slaughter areas, evisceration and offal areas.

Minimise cross contamination by enforcing colour coding.

Clean and sanitise:

Drains, chillers (door handles), non production equipment esp. that moving between departments = ladders, tool boxes, trolleys (wheels).

Treat with residual sanitisers, air circulating equipment = condensers, drip trays, fans, vents.

Sanitise ceilings and monitor condensate.

Check toilet facilities including hand washing.

Acid Wash – This should be used in all cases of Pathogen or high bacterial counts.

It removes scale, which is a base for biofilms.

It will aid removal of biofilms.

The acidic environment will at least inhibit, if not halt the growth of bacteria.

If followed by standard alkaline wash, the resultant pH shock will again kill off most bacteria, and at least severely inhibit growth.

The alternative sanitizer (prescribed as part of acid wash), will at least inhibit, if not halt the growth of bacteria.

Monitoring

Movement of staff and materials between slaughter and other departments.

Monitor crates and lugs with extra swabbing. Raw material handling including delivery containers.

Review production facility swab results. Plot positive results on scale site plan, look for common factors e.g. Engineering movement, drain flow.

Monitor condensate.

Reference

Modern Food Microbiology

Now is the time to find out how BioGiene

can save you money and protect your brand.

Why choose BioGiene

BioGiene provides a specialised Food Processing facility cleaning and sanitation service, delivering our partners improved value, and brand security.

There are 8 great reasons to choose BioGiene as your cleaning professionals.

Core Business focus

Designated Manager

Fully Auditable

Site Specific

FULLY CERTIFIED

STAFF OUTCOMES

BUYING POWER

CLEANING OUTCOMES

- Food Factory Cleaning is our core business focus. We are specialists and highly experienced in industries such as:

Beef

Pork

Poultry

Ready to Eat

2. All our clients have a Designated Manager, which ensures ownership and accountability for quality outcomes.

Your Designated Manager is your one point of contact for anything cleaning-related – reporting, issues, questions, compliments, complaints.

3. Our systems are fully auditable, so we comply with all necessary regulations, and can provide documentation to support your own audit requirements, and requests for information.

4. We use Site Specific Integrated Management Systems (Quality & WHS), meaning we tailor our processes for our client needs, and gather everything into a formal document, which is auditable.

5. We are certified in ISO Systems (Quality 9001:2015 & Safety 45001:2018).

6. Our Ethical and transparent recruitment & onboarding processes improve staff outcomes. We have recently passed a SMETA (Sedex Members Ethical Trade Audit) conducted by Sedex, confirming our high standards of labour, health and safety, environment and business ethics.

7. Our size allows us increased buying power and better access to required chemicals, cleaning tools and skilled labour. We also maintain direct access to the latest technology and modern equipment solutions.

8. Our robust processes, transparent staffing and documented procedures will give you confidence in your cleaning outcome on a consistent basis.

1

Food Factory Cleaning is our core business focus.

We are specialists and highly experienced in industries such as:

Seafood

Small Goods

Fresh Produce

Ready to Eat

2

All our clients have a Designated Manager, which ensures ownership and accountability for quality outcomes.

Your Designated Manager is your one point of contact for anything cleaning-related – reporting, issues, questions, compliments, complaints.

3

Our systems are fully auditable, so we comply with all necessary regulations, and can provide documentation to support your own audit requirements, and requests for information.

4

We use Site Specific Integrated Management Systems (Quality & WHS), meaning we tailor our processes for our client needs, and gather everything into a formal document, which is auditable.

5

We are certified in ISO Systems (Quality 9001:2015 & Safety 45001:2018).

6

Our Ethical and transparent recruitment & onboarding processes improve staff outcomes. We have recently passed a SMETA (Sedex Members Ethical Trade Audit) conducted by Sedex, confirming our high standards of labour, health and safety, environment and business ethics.

7

Our size allows us increased buying power and better access to required chemicals, cleaning tools and skilled labour. We also maintain direct access to the latest technology and modern equipment solutions.

8

Our robust processes, transparent staffing and documented procedures will give you confidence in your cleaning outcome on a consistent basis.